Light

warps of thin records can generally be corrected on the turntable during

play using a  Peripheral

record ring. But after the record has been played, the warp just stays.

To correct more severe warps in heavy records a heavier ring must be used.

But then correction is not always possible - this is so in my experience

as I have both a light weight peripheral ring and a heavy metal ring as

well. Peripheral

record ring. But after the record has been played, the warp just stays.

To correct more severe warps in heavy records a heavier ring must be used.

But then correction is not always possible - this is so in my experience

as I have both a light weight peripheral ring and a heavy metal ring as

well. |

|

| So

what to do with warped records? First let's have a look at those in a box.

Examine what sort of warp you are dealing with. Is there a curve at the

periphery at one spot caused by sagging or does the record have the shape

of a dish? First of all get rid of the soft plastic foam. Plastic foam was

maybe right at the time of production, but after so many years it certainly

has deteriorated and has lost its elasticity and consistency.

If there

is a cardboard filler, it should be sturdy and completely flat. If it is

not, throw it away as well or keep it but outside the box. |

|

|

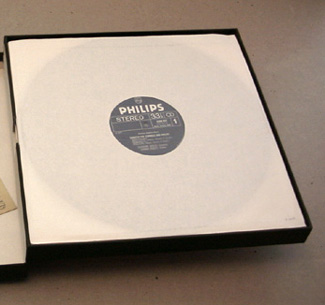

Now

measure the size of the compartment: height and width.

|

|

| Cut

out squares of thick cardboard and make sure that they can be placed

into the box easily. |

|

| Cut

off one small corner so you will be able to take out the cardboard filler

easily if necessary. |

|

| Use

the cardboard sheet as a replacement of whatever filler there was in the

box before. See to it that the cardboard is flat and sturdy. You can choose

the thickness in relation to the space (room) you want to fill up. In the

picture at right you see ordinary cardboard. If you want you can buy a nicer

material in the art supply shop.

But it should always be completely flat and have no tendency to bend easily. |

|

| Put

the records in the box. See to it that there is no room left for sagging. |

|

|

If there is room left it is necessary to

put an extra square sheet of cardboard on top of the records before adding

the document (book or inlay). Hopefully the documents have the size of a

record and are not the smaller booklets often provided by EMI in Great Britain.

Then close the box and store it vertically. This will prevent warping and

will help correcting light warps over time. As a matter of fact in this

way time is your aid. |

|

|

So

if you encounter a box containing warped or concave records, do not throw

these away. Just fill up the empty space and make sure that there is no

room left when the box is closed! A tight fit is necessary. Store the

box on the shelf so that it is supported on both sides by other boxes

and records. It is better to store records and boxes rather tightly instead

of loose. You may discover that after a couple of weeks or a month the

records will have flattened.

It

goes without saying that the records should be cleaned or at least dusted

off with a carbon fiber record brush and with a velvet brush as well.

And see to it that the paper sleeves are free of dust particles also.

|

|

|

This method will also work with individual

records. If you have an empty box, you can follow the method described

above. Take the records out of the outer covers and place them in between

cardboard sheets. If you do not have a box at your disposal place the

records as shown in the drawing and keep them tightly stored for at least

a month. This method works only with vinyl from the 1960s, 1970s and 1980s.

Not always for 1950s mono disks. Give it a try. And if it does not work

you always can take more drastic measures.

I

bought a box with the complete chamber music of Johannes Brahms. The records

were hollow shaped like saucers. I did put several sheets of cardboard

in the box. And guess what? After 2 months I discovered that the records

were flat again and remained so. And it also worked with Mozart's Violin

Music played by Henryk Szeryng and Ingrid Haebler as illustrated on this

page.

|

|

| |

|

| It

is important to check the LP cover. Sturdy cardboard covers may be no longer

completely flat. Chances are that a new warp will be produced easily. Also

gate fold covers may do harm and be the cause of a slight warp at the spine,

typically when it contains 2 records. In some cases it can be wise to put

one or more LP's in a generic cardboard cover. |

|

| |

|

In the olden days of thick flat mono records, warps were

brought about through mishandling a record by the owner.

In the olden days of thick flat mono records, warps were

brought about through mishandling a record by the owner.